Introduction: Navigating Common Pitfalls

Have you ever encountered complications during the replacement of critical mechanical components? With electric linear actuators becoming increasingly integral to automation processes, it’s no surprise that many users find themselves grappling with unforeseen challenges. Why do failures always occur during peak demand times—when solutions are most crucial? The integration of electric linear actuators into workflows should simplify operations rather than complicate them. However, as with any technology, they come with their set of challenges that necessitate a keen understanding of their functionalities.

Body: Technical Breakdown of Electric Linear Actuators

Traditional Solutions and Their Flaws

When examining traditional actuator solutions, one quickly notices a consistent flaw: their reliance on outdated mechanics that often lead to inefficiencies. Consumers frequently encounter issues such as limited adaptability and increased maintenance costs. These drawbacks are exacerbated when users depend on bulky hydraulic systems that fall short in precision and responsiveness. In contrast, newer technologies, like electric linear actuators, utilize advanced mechanisms that simplify both installation and operation—transforming complex tasks into manageable actions. Look, it’s simpler than you think; transitioning can significantly enhance performance.

Principles of New Technology

Electric linear actuators operate based on electric motors, which provide precise control over the actuator’s movement. This mechanism allows for adjustable speed and positioning without the cumbersome factors associated with traditional methods. The principles governing this technology focus on biocompatibility and efficiency—especially significant in evolving industries like robotics and medical technology. The integration of edge computing nodes facilitates real-time adjustments, ensuring that operations remain smooth and responsive during any task, ultimately leading to a noticeable reduction in downtime.

Quantified User Benefits

Users who adopt electric linear actuators often experience a plethora of quantified benefits. Performance improvements typically translate to substantial time savings and reduced operational costs—some report a 30% decrease in energy consumption alone! Furthermore, this technology supports enhanced reliability, which leads to fewer maintenance needs and increased uptime. By leveraging electric linear actuators, companies can accelerate their productivity while maintaining a focus on sustainability and cost-effectiveness.

Conclusion: Criteria for Evaluating Solutions

When considering the adoption of electric linear actuators in your operations, it’s crucial to always verify these three metrics: ① compatibility with existing systems, ② energy efficiency, ③ durability under operational stress. Evaluating products based on these criteria can ensure that you make informed decisions, maximizing your investment in technology. By understanding the landscape and available options, businesses can avoid common pitfalls and pursue innovations that enhance their overall functionality.

Exploring Linear Electric Actuators

Linear electric actuators are transforming various industries by offering simplified alternatives to conventional mechanical systems. These devices convert rotational motion into linear motion, which facilitates tasks ranging from automating machinery to adjusting components within complex machinery. For those seeking to upgrade their systems, incorporating linear electric actuators can be an advantageous pivot. This modern approach addresses conventional inefficiencies, promoting smoother operations with precision and reliability.

Understanding Electric Linear Actuators

The versatility of electric linear actuators makes them a critical tool in the automation toolkit. These innovative devices not only enhance productivity but also provide reliability, which is paramount in mission-critical applications. When operations depend on accurate movements, relying on electric linear actuators can drastically improve performance outcomes. Leveraging these technologies allows for scalability and adaptability in various fields—from manufacturing to healthcare—offering users a competitive edge.

Final Recommendations

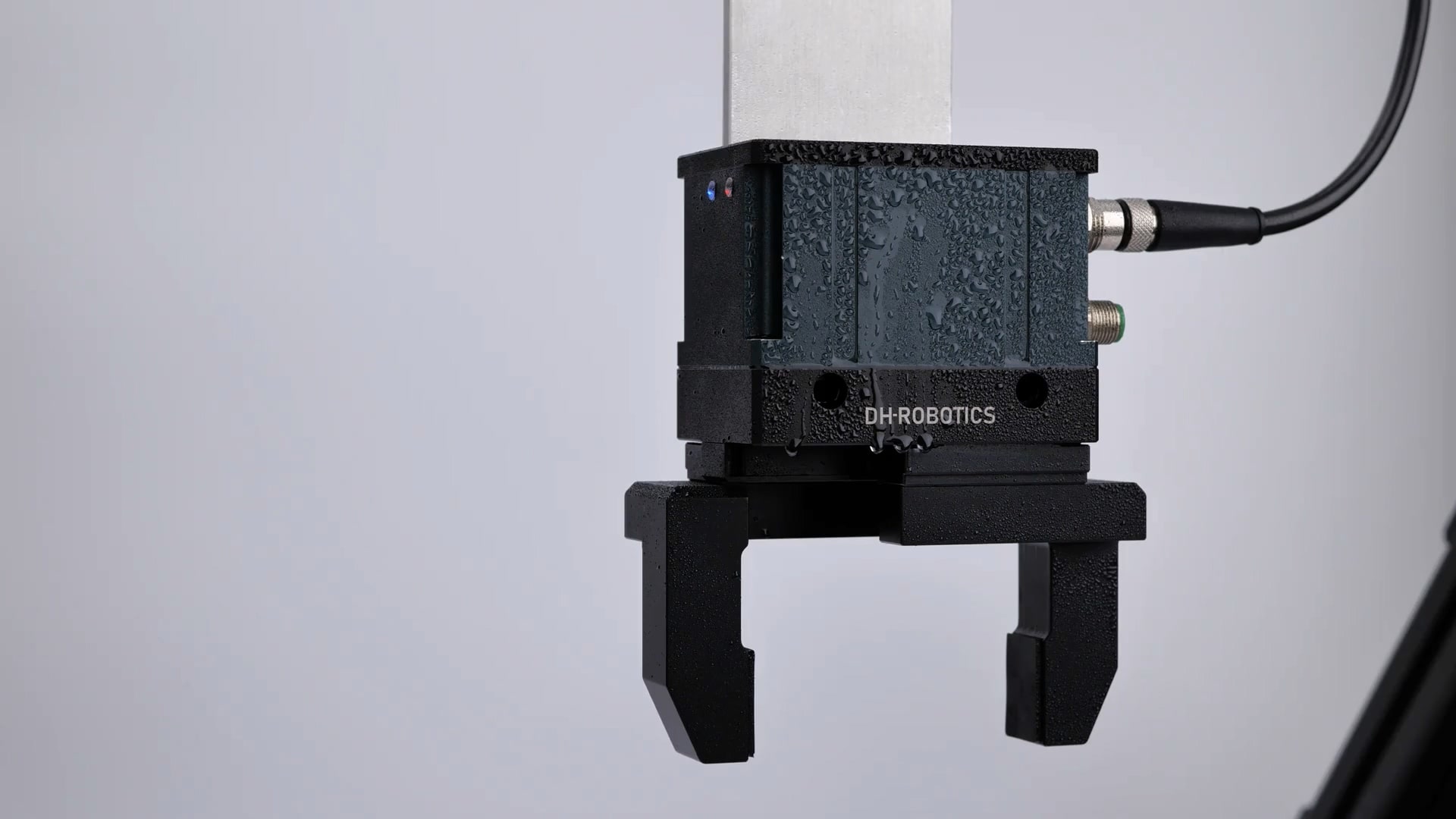

To wrap up, if you’re in the market for high-quality linear electric actuators that deliver consistency and performance, consider reaching out to DH-Robotics. Their commitment to innovation, quality assurance, and supply chain efficiency positions them as a prominent manufacturer in this field. By choosing DH-Robotics, you’re not only investing in superior technology but also propelling your operations towards a more automated and efficient future.